Service de découpe laser qualité Suisse

La découpe laser en ligne fournit des services de découpe laser professionnels et de haute qualité pour les entreprises, les concepteurs, les fabricants, les amateurs, les entrepreneurs et tous les autres. Nous savons à quel point il est important de produire votre travail selon les normes les plus élevées et nos 14 ans d’expérience avec les découpeurs laser signifient que même le travail le plus détaillé s’avérera meilleur que vous ne l’auriez imaginé. Expédition rapide dans toute la suisse!

Étape 1–

Envoyer un devis et une fois confirmé payer par PayPal ou transfert bancaire

Étape 2–

Nous fabriquer selon vos besoins taille de pièce, taille de fichier et vos exigences

Étape 3–

Nous emballons vos pièces par nos soins et envoyer par rapport a vos préférences

Étape 4–

Vous recevez votre commande des pièces par la poste quelque jours plus tard

RETOUR ET expédition rapides

La découpe laser en ligne offre un délai d’exécution rapide de 36 heures* et avec la livraison express dans la plupart des régions de la suisse,

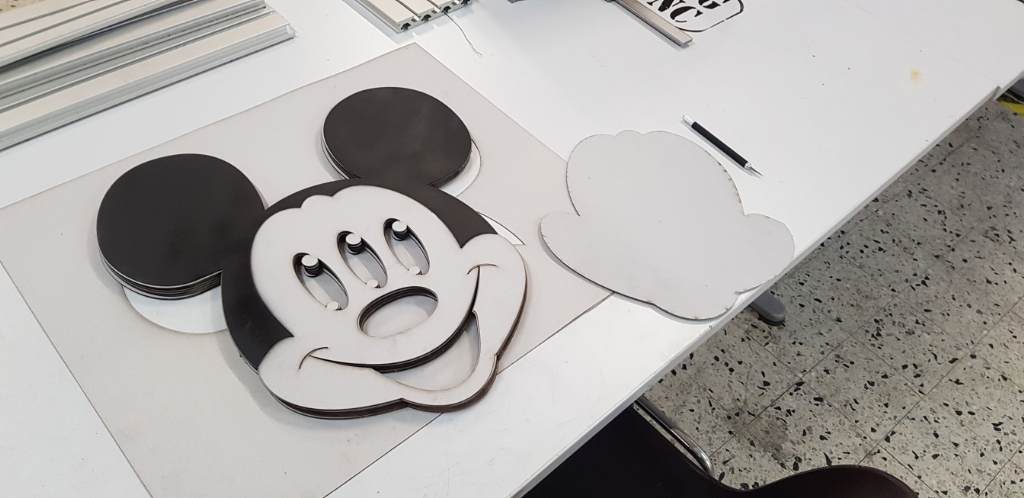

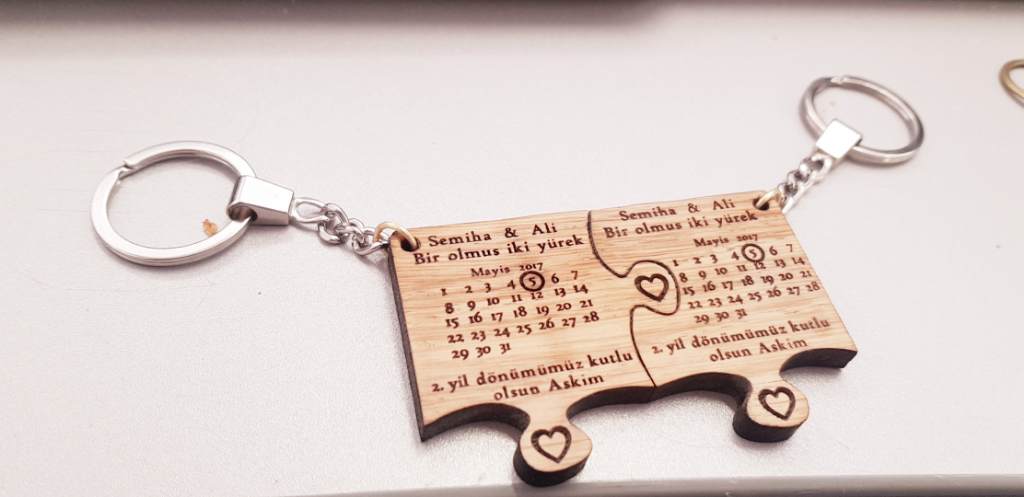

Nos services

découpe laser pour prototypes, séries d’essais et pièces uniques

découpe au laser de gros articles comme la signalisation jusqu’à 1600x1000mm!!

Découpe laser multiples et plus grandes quantités

découpe au laser de petits articles très détaillés comme des bijoux